DEFORM

Transactions of Materials Processing Simulation

DEFORM

Transactions of Materials Processing Simulation

DEFORM

A simulation software for transactions of materials processing using FEM

DEFORM is an engineering program that simulates the transactions of materials processing using the FEM and it is currently the most widely used forging and transactions of materials processing simulation software worldwide.

For over 30 years, companies in many countries worldwide have contributed greatly to the reduction of development cost and period and quality improvement for the processing simulation using DEFORM, and its reliability and efficiency have been proven in a wide range of researches and industrial applications.

For over 30 years, companies in many countries worldwide have contributed greatly to the reduction of development cost and period and quality improvement for the processing simulation using DEFORM, and its reliability and efficiency have been proven in a wide range of researches and industrial applications.

DEFORM Products

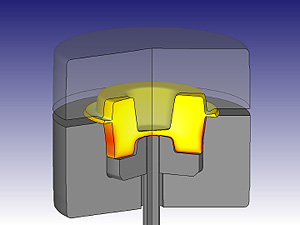

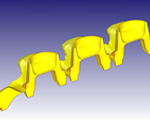

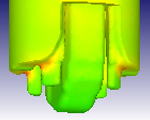

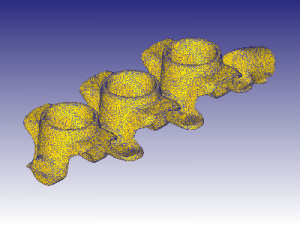

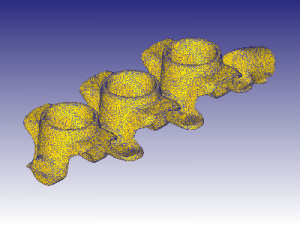

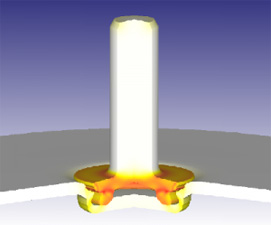

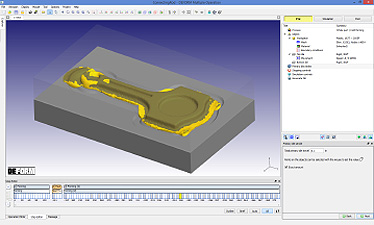

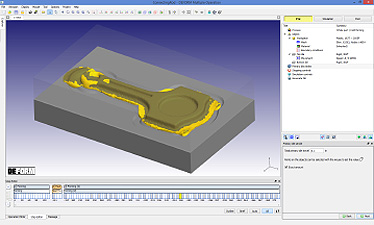

1. DEFORM-3D

DEFORM-3D is a process simulation system designed to analyze the transactions of materials processing in three dimensions.

It is a powerful, convenient and reliable analysis program capable of interpreting the behavior of complex materials in three dimensions as a practical tool.

It is a powerful, convenient and reliable analysis program capable of interpreting the behavior of complex materials in three dimensions as a practical tool.

Applicable Fields

Cold forging, hot forging, free forging, rolling, extrusion, drawing, spinning, machining, pressing, sintering, etc.

It provides the combined behavior of deformation, heat transfer, and forming equipment in an integrated system environment.

The material flow, filling, forming load, die stress, and defects can be predicted in cold, warm, and hot processes.

The types of material available for use include elastic body, rigid-plastic body, elastic-plastic body, powder, rigid body and user-defined material.

Press settings for the forming process include the use of speed and load as well as hydraulic, hammer-type, screw-type, mechanical press, and user-defined subroutines.

Through the powerful after-treatment machine, it is possible to track the deformation, state variables, loads, and the position of material flow and predict the flow lines.

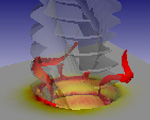

Processes such as shearing, piercing, and cutting can be interpreted using well-known failed models.

User-defined subroutines can define the flow stress, press actions, cracks, etc., and can also be used for special after-treatment such as micro-structure and mechanical properties.

It provides the combined behavior of deformation, heat transfer, and forming equipment in an integrated system environment.

The material flow, filling, forming load, die stress, and defects can be predicted in cold, warm, and hot processes.

The types of material available for use include elastic body, rigid-plastic body, elastic-plastic body, powder, rigid body and user-defined material.

Press settings for the forming process include the use of speed and load as well as hydraulic, hammer-type, screw-type, mechanical press, and user-defined subroutines.

Through the powerful after-treatment machine, it is possible to track the deformation, state variables, loads, and the position of material flow and predict the flow lines.

Processes such as shearing, piercing, and cutting can be interpreted using well-known failed models.

User-defined subroutines can define the flow stress, press actions, cracks, etc., and can also be used for special after-treatment such as micro-structure and mechanical properties.

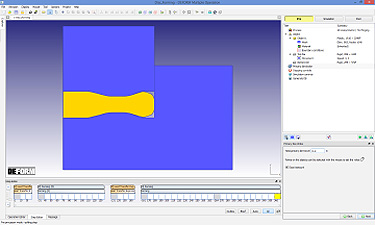

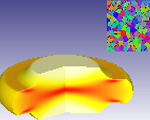

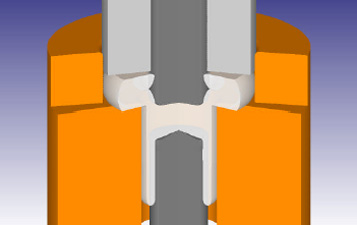

2. DEFORM-2D

DEFORM-2D is a powerful process simulation system designed to analyze the two-dimensional flow of complex metal forming processes using axial symmetry and plane strain.

Applicable Fields

Cold forging, hot forging, rolling, extrusion, drawing

It provides the combined behavior of deformation, heat transfer, and forming equipment in an integrated system environment.

The material flow, filling, forming load, die stress, and defects can be predicted in cold, warm, and hot processes.

Two-dimensional analysis of plane strain and axial symmetry conditions and 2-1/2-dimensional analysis of constant surface flow are possible.

The polymorphic deformable body capability can simultaneously analyze the deformation of composites or materials and molds.

A very efficient one-step die stress analysis that includes the use of reinforcing ring can be possible.

Through the self-tangency condition, continuous performance of analysis can be possible even after a folding defect occurs.

User-defined subroutines can define the flow stress, press actions, cracks, etc., and can also be used for special after-treatment such as micro-structure and mechanical properties.

It provides the combined behavior of deformation, heat transfer, and forming equipment in an integrated system environment.

The material flow, filling, forming load, die stress, and defects can be predicted in cold, warm, and hot processes.

Two-dimensional analysis of plane strain and axial symmetry conditions and 2-1/2-dimensional analysis of constant surface flow are possible.

The polymorphic deformable body capability can simultaneously analyze the deformation of composites or materials and molds.

A very efficient one-step die stress analysis that includes the use of reinforcing ring can be possible.

Through the self-tangency condition, continuous performance of analysis can be possible even after a folding defect occurs.

User-defined subroutines can define the flow stress, press actions, cracks, etc., and can also be used for special after-treatment such as micro-structure and mechanical properties.

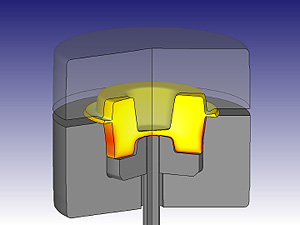

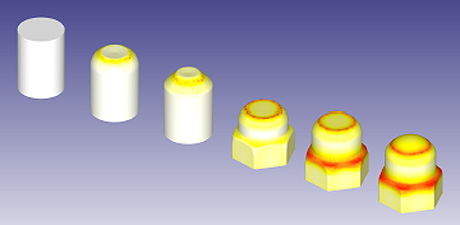

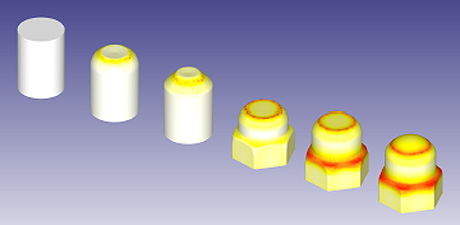

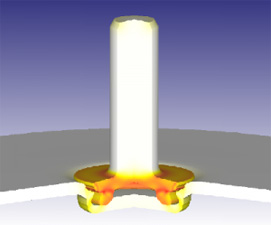

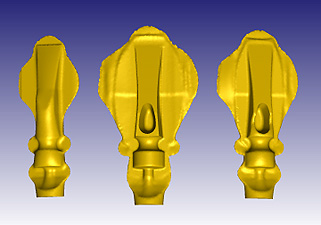

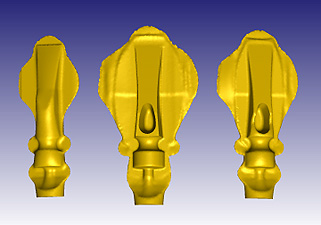

3. DEFORM-F3

DEFORM-F3 is an exclusive 3D forging simulation program developed mainly for the core functions of DEFORM-3D.

It is designed to allow users with little simulation experience to use it very easily.

Forging problems with complex shapes can also be simulated very easily through an intuitive user interface.

The material flow, filling, forming load, die stress, and defects can be analyzed in cold, warm, and hot processes.

It is designed to allow users with little simulation experience to use it very easily.

Forging problems with complex shapes can also be simulated very easily through an intuitive user interface.

The material flow, filling, forming load, die stress, and defects can be analyzed in cold, warm, and hot processes.

Applicable Fields

Cold forging, hot forging, extrusion, drawing

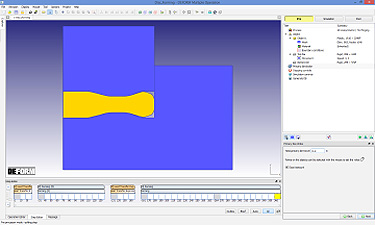

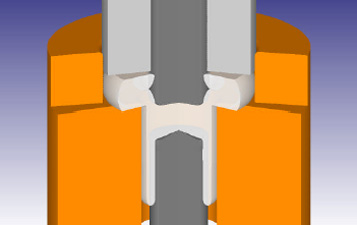

4. DEFORM-F2

DEFORM-F2 is an exclusive program for 2D forging simulation developed mainly for the core functions of DEFORM-2D.

It is designed to allow users with little simulation experience to use it very easily.

The simulation type is capable of displaying axial symmetry and plane strain.

It is designed to allow users with little simulation experience to use it very easily.

The simulation type is capable of displaying axial symmetry and plane strain.

Applicable Fields

Cold forging, hot forging, extrusion, drawing