AutoPIPE Vessel

Faster time to production

AutoPIPE Vessel

Faster time to production

AutoPIPE Vessel

Vessel Design Software

Design and Model Pressure Vessels

Generate Vessel Detail Drawings

Reference Piping Model for Vessel Analysis

AutoPIPE Vessel provides you with cost-effective and accurate design of pressure vessels, heat exchangers, tanks, and air coolers. Reduce mistakes and time consuming manual revisions. Ensure greater efficiency with your supply chain and improved collaboration with engineering companies. Increase your efficiency through fully automatic vessel design optimization under all installation and operating conditions.

Increase productivity and provide accurate design for the safe operation of vessels under all loading conditions for pressure vessels, heat exchangers, tanks, and air coolers. Achieve compliance with regional and global standards, including pressure vessel design codes from the past 10 years and regional wind, seismic, wave, and blast-loading codes. Improve flexibility for re-rating and revamping existing vessels. You can design for both brownfield and greenfield projects, and shorten design time and rework by eliminating guesswork. Ensure confidence in vessel design and improve your competitiveness through higher design quality.

Increase productivity and provide accurate design for the safe operation of vessels under all loading conditions for pressure vessels, heat exchangers, tanks, and air coolers. Achieve compliance with regional and global standards, including pressure vessel design codes from the past 10 years and regional wind, seismic, wave, and blast-loading codes. Improve flexibility for re-rating and revamping existing vessels. You can design for both brownfield and greenfield projects, and shorten design time and rework by eliminating guesswork. Ensure confidence in vessel design and improve your competitiveness through higher design quality.

Compliance with codes and industry standards

Compliance with codes and industry standards

Integration of pipeline models into vessel analysis environments

Integration of pipeline models into vessel analysis environments

AutoPIPE Vessel Capabilities

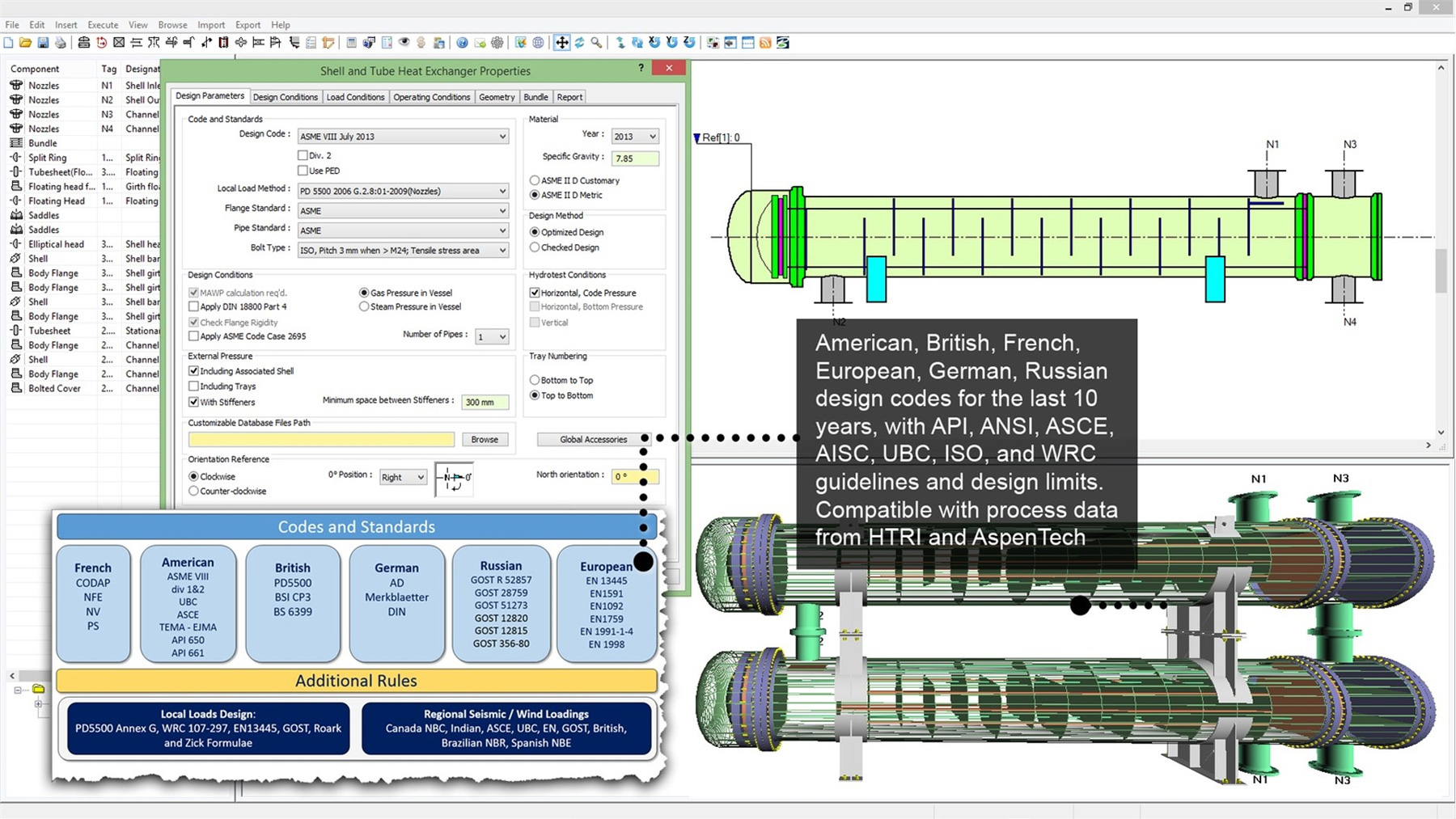

Comply with industry codes and standards

Ensure your projects comply with more than 30 global design standards across the power, nuclear, offshore, chemical, and oil and gas industries. Incorporate ASME, British, European, French, Japanese, Russian, API, NEMA, ANSI, ASCE, AISC, UBC, ISO, and WRC guidelines and design limits.

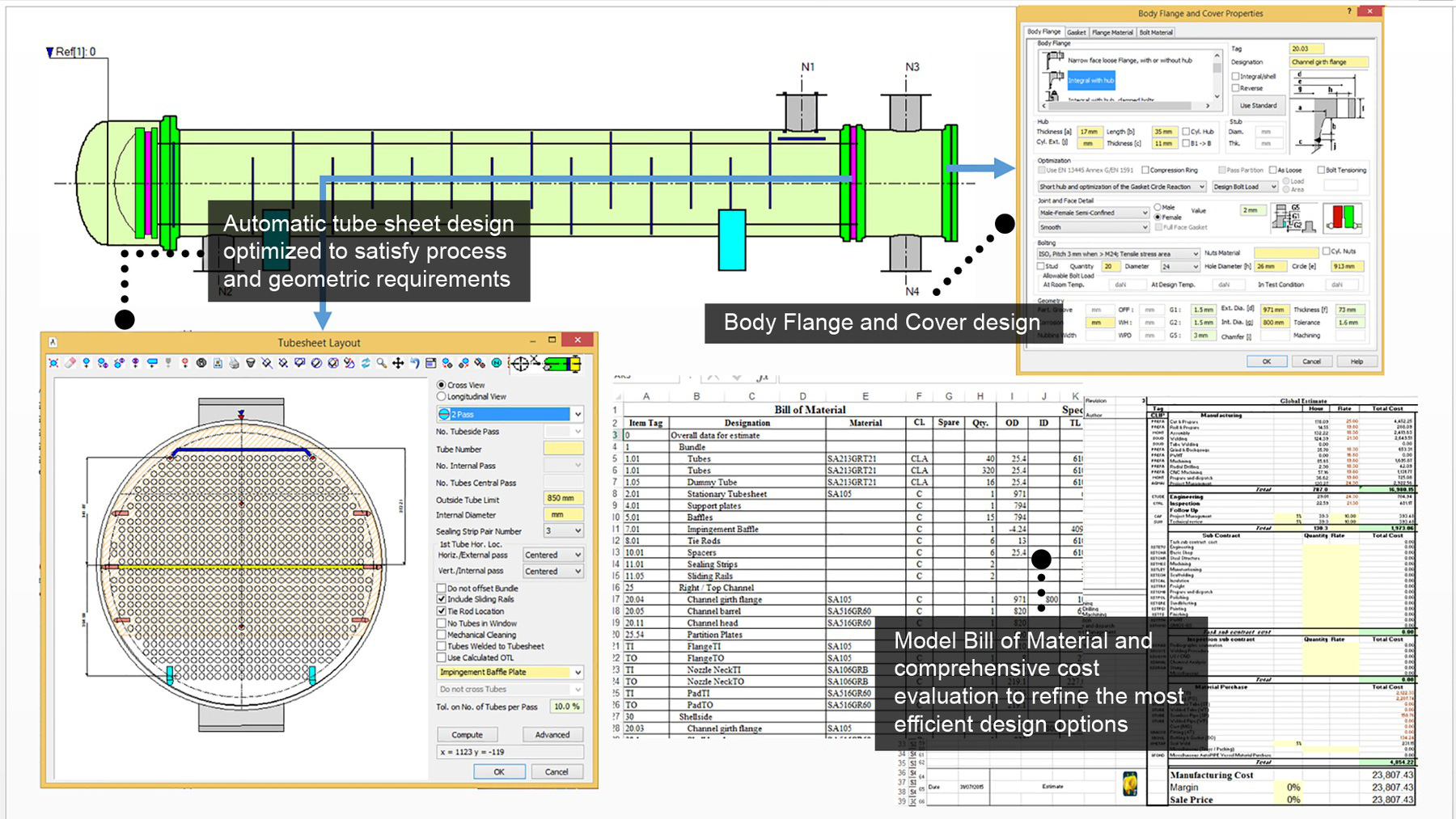

Design and model pressure vessels

Quickly design and model pressure vessels based on international design codes and local load methods. Optimize your flange design to minimize costs based on design codes, ensuring safe vessel design. Generate bills of material, detailed vessel drawings, and detailed parametric 3D solid models.

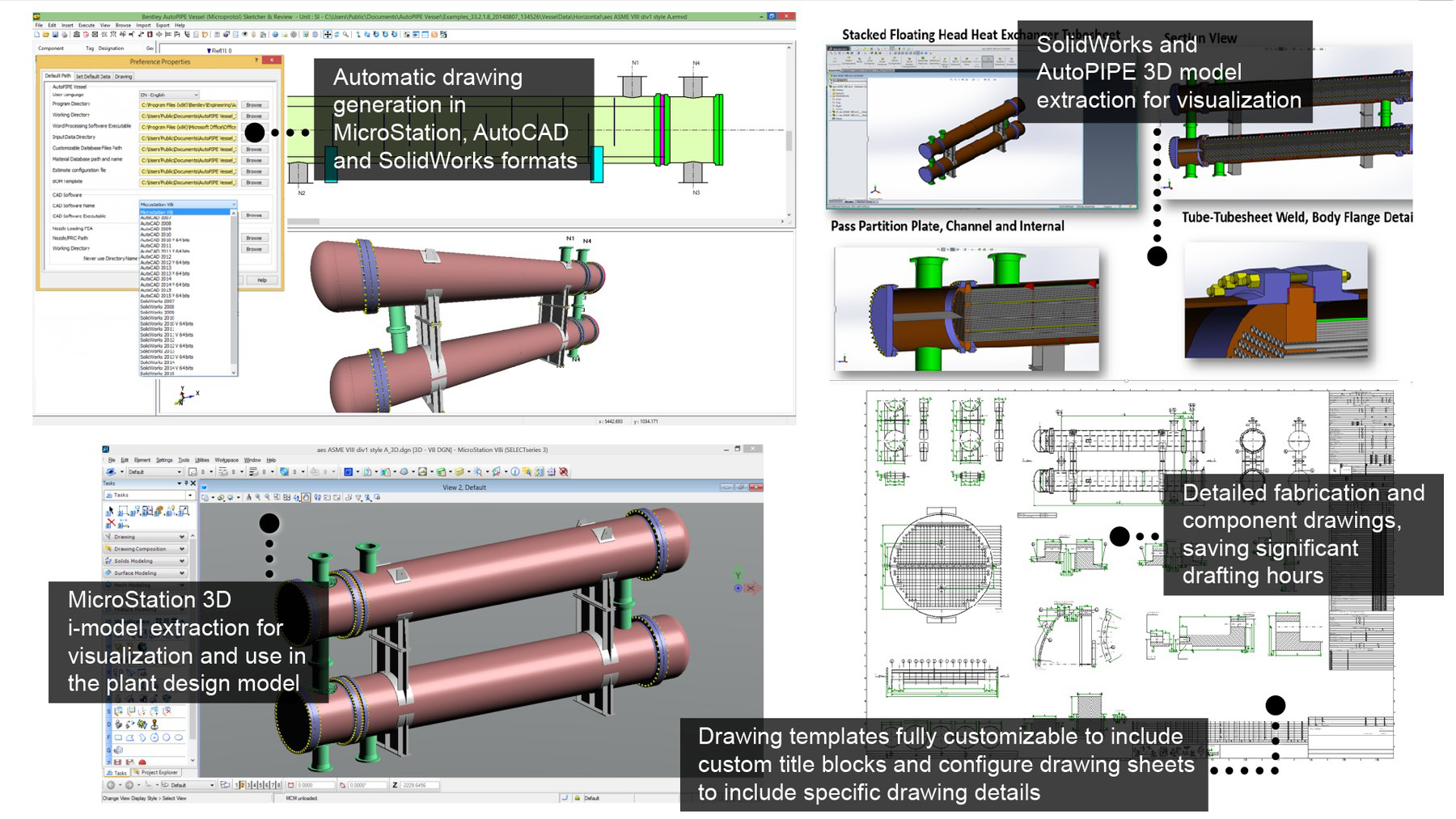

Generate vessel detail drawings

Reduce manual drawing time and rework with automated detailed drawings. Create fully dimensioned engineering drawings, managing white space and configuring drawing sheet layout. Customize data and connection details to meet manufacturer standards.

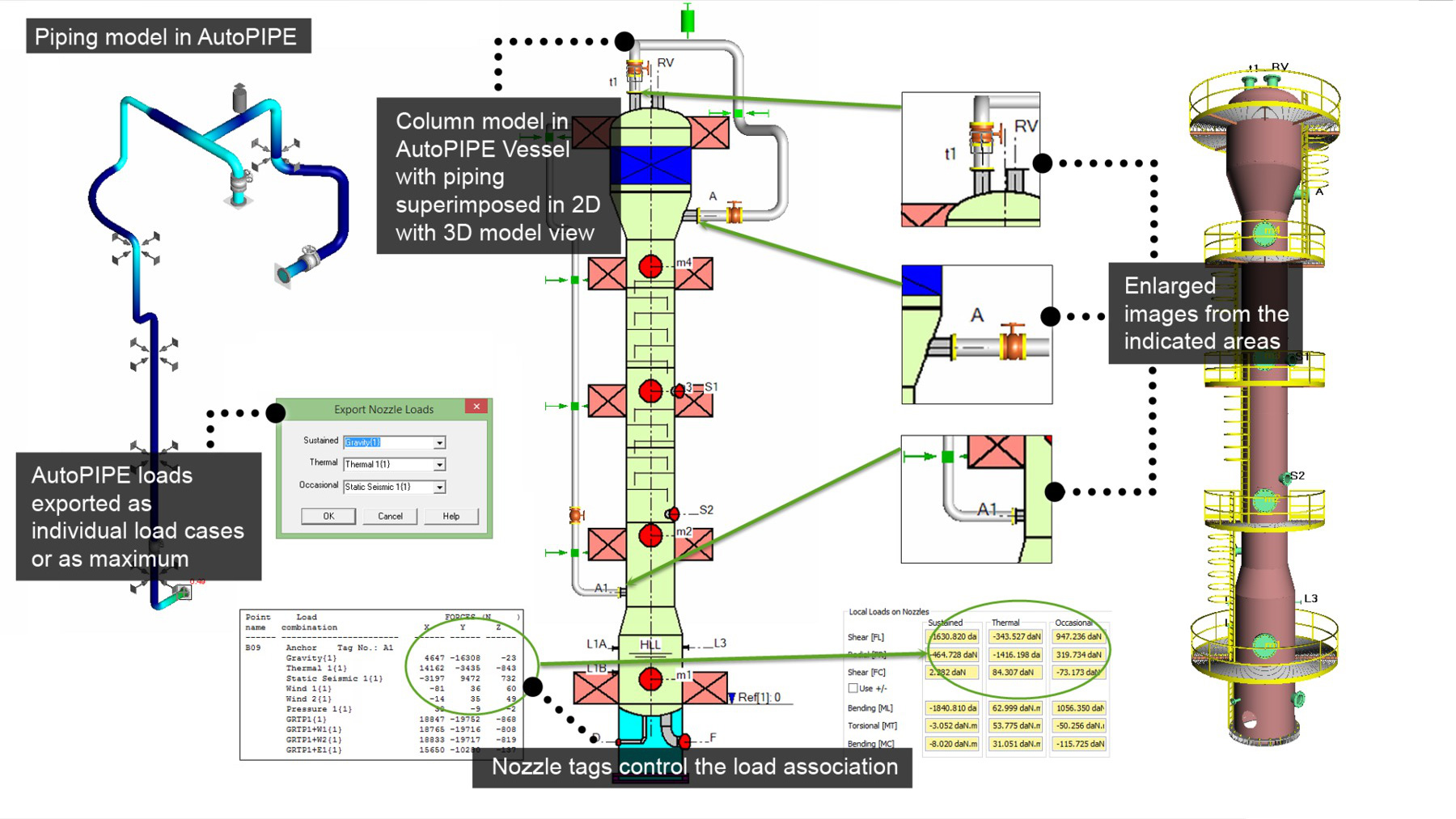

Reference piping model for vessel analysis

Save time and reduce errors by importing nozzle loads from AutoPIPE into AutoPIPE Vessel for analysis as a local load on the vessel shell.